Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel,is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength. Rebar significantly increases the tensile strength of the structure. Rebar's surface features a continuous series of ribs, lugs or indentations to promote a better bond with the concrete and reduce the risk of slippage.

Rebar Type:

The most common type of rebar is carbon steel, typically consisting of hot-rolled round bars with deformation patterns embossed into its surface. Steel and concrete have similar coefficients of thermal expansion, so a concrete structural member reinforced with steel will experience minimal differential stress as the temperature changes.

Other readily available types of rebar are manufactured of stainless steel, and composite bars made of glass fiber, carbon fiber, or basalt fiber. The carbon steel reinforcing bars may also be coated in zinc or an epoxy resin designed to resist the effects of corrosion, especially when used in saltwater environments. Bamboo has been shown to be a viable alternative to reinforcing steel in concrete construction.These alternative types tend to be more expensive or may have lesser mechanical properties and are thus more often used in specialty construction where their physical characteristics fulfil a specific performance requirement that carbon steel does not provide.

Application Scenarios:

Use in concrete and masonry

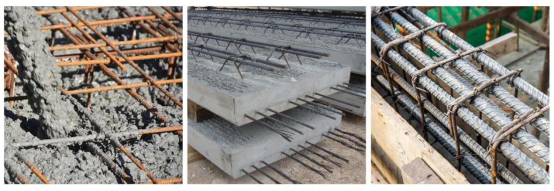

Concrete is a material that is very strong in compression, but relatively weak in tension. To compensate for this imbalance in concrete's behavior, rebar is cast into it to carry the tensile loads. Most steel reinforcement is divided into primary and secondary reinforcement:

· Primary reinforcement refers to the steel which is employed to guarantee the resistance needed by the structure as a whole to support the design loads.

· Secondary reinforcement, also known as distribution or thermal reinforcement, is employed for durability and aesthetic reasons, by providing enough localized resistance to limit cracking and resist stresses caused by effects such as temperature changes and shrinkage.

Secondary applications include rebar embedded in masonry walls, which includes both bars placed horizontally in a mortar joint (every fourth or fifth course of block) or vertically (in the horizontal voids of cement blocks and cored bricks, which is then fixed in place with grout. Masonry structures held together with grout have similar properties to concrete – high compressive resistance but a limited ability to carry tensile loads. When rebar is added they are known as "reinforced masonry".

A similar approach (of embedding rebar vertically in designed voids in engineered blocks) is also used in dry-laid landscape walls, at least pinning the lowest course in place into the earth, also employed securing the lowest course and/or deadmen in walls made of engineered concrete or wooden landscape ties.

In unusual cases, steel reinforcement may be embedded and partially exposed, as in the steel tie bars that constrain and reinforce the masonry of Nevyansk Tower or ancient structures in Rome and the Vatican.

Physical characteristics

Steel has a thermal expansion coefficient nearly equal to that of modern concrete. If this were not so, it would cause problems through additional longitudinal and perpendicular stresses at temperatures different from the temperature of the setting.Although rebar has ribs that bind it mechanically to the concrete, it can still be pulled out of the concrete under high stresses, an occurrence that often accompanies a larger-scale collapse of the structure. To prevent such a failure, rebar is either deeply embedded into adjacent structural members (40–60 times the diameter), or bent and hooked at the ends to lock it around the concrete and other rebar. This first approach increases the friction locking the bar into place, while the second makes use of the high compressive strength of concrete.

Common rebar is made of unfinished tempered steel, making it susceptible to rusting. Normally the concrete cover is able to provide a pH value higher than 12 avoiding the corrosion reaction. Too little concrete cover can compromise this guard through carbonation from the surface, and salt penetration. Too much concrete cover can cause bigger crack widths which also compromises the local guard. As rust takes up greater volume than the steel from which it was formed, it causes severe internal pressure on the surrounding concrete, leading to cracking, spalling, and, ultimately, structural failure. This phenomenon is known as oxide jacking.

Requirements for deformations are found in US-standard product specifications for steel bar reinforcing, such as ASTM A615 and ASTM A706, and dictate lug spacing and height.

Fibre-reinforced plastic rebar is also used in high-corrosion environments. It is available in many forms, such as spirals for reinforcing columns, common rods, and meshes. Most commercially available rebar is made from unidirectional fibers set in a thermoset polymer resin, and is often referred to as FRP.

Some special construction such as research and manufacturing facilities with very sensitive electronics may require the use of reinforcement that is non-conductive to electricity, and medical imaging equipment rooms may require non-magnetic properties to avoid interference. FRP rebar, notably glass fibre types have low electrical conductivity and are non-magnetic which is commonly used for such needs. Stainless steel rebar with low magnetic permeability is available and is sometimes used to avoid magnetic interference issues.

Reinforcing steel can also be displaced by impacts such as earthquakes, resulting in structural failure. The shaking of the earthquake caused rebars to burst from the concrete and buckle. Updated building designs, including more circumferential rebar, can address this type of failure.

Historically in Europe, rebar is composed of mild steel material with a yield strength of approximately 250 MPa (36 ksi). Modern rebar is composed of high-yield steel, with a yield strength more typically 500 MPa (72.5 ksi). Rebar can be supplied with various grades of ductility. The more ductile steel is capable of absorbing considerably more energy when deformed - a behavior that resists earthquake forces and is used in design. These high yield strength ductile steels are usually produced using the TEMPCORE process, a method of thermomechanical processing. The manufacture of reinforcing steel by re-rolling finished products (e.g. sheets or rails) is not allowed. In contrast to structural steel, rebar steel grades are not harmonized yet across Europe, each country having their own national standards. However some standardization of specification and testing methods exist under EN 10080 and EN ISO 15630:

BS EN 10080: Steel for the reinforcement of concrete. Weldable reinforcing steel. General.

BS 4449: Steel for the reinforcement of concrete. Weldable reinforcing steel. Bar, coil and decoiled product. Specification.

BS 4482: Steel wire for the reinforcement of concrete products. Specification.

BS 4483: Steel fabric for the reinforcement of concrete. Specification.

BS 6744: Stainless steel bars for the reinforcement of and use in concrete. Requirements and test methods.

DIN 488-1: Reinforcing steels - Part 1: Grades, properties, marking.

DIN 488-2: Reinforcing steels - Part 2: Reinforcing steel bars.

DIN 488-3: Reinforcing steels - Part 3: Reinforcing steel in coils, steel wire.

DIN 488-4: Reinforcing steels - Part 4: Welded fabric.

DIN 488-5: Reinforcing steels - Part 5: Lattice girders.

DIN 488-6: Reinforcing steel - Part 6: Assessment of conformity.

BS EN ISO 15630-1: Steel for the reinforcement and prestressing of concrete. Test methods. Reinforcing bars, wire rod and wire.

BS EN ISO 15630-2: Steel for the reinforcement and prestressing of concrete. Test methods. Welded fabric.

Commonly used steel bar production standards in China:

(1) Steel for reinforced concrete Part 1: Hot-rolled smooth round steel bar GB/T 1499.1-2017

(2) Steel for reinforced concrete Part 2: Hot-rolled ribbed steel bars GB1499.2-2018

(3) Steel for reinforced concrete Part 3: Welded steel mesh GB1499.3-2010

(4) Quenching and self-tempering ribbed bars for the reinforcement of concrete GB13014-2013

(5) Low carbon steel hot-rolled round wire rod GB/T701-2008

(6) Cold-rolled ribbed steel bar GB/T 13788-2017

(7) Steel wire for prestressed concrete GB/T 5223-2014

(8) Steel strand for prestressed concrete GB/T 5224-2014

(9) Cold-drawn spiral steel bar DBJ14-BG3-96

BS EN 10080: Steel for the reinforcement of concrete. Weldable reinforcing steel. General.

BS 4449: Steel for the reinforcement of concrete. Weldable reinforcing steel. Bar, coil and decoiled product. Specification.

BS 4482: Steel wire for the reinforcement of concrete products. Specification.

BS 4483: Steel fabric for the reinforcement of concrete. Specification.

BS 6744: Stainless steel bars for the reinforcement of and use in concrete. Requirements and test methods.

DIN 488-1: Reinforcing steels - Part 1: Grades, properties, marking.

DIN 488-2: Reinforcing steels - Part 2: Reinforcing steel bars.

DIN 488-3: Reinforcing steels - Part 3: Reinforcing steel in coils, steel wire.

DIN 488-4: Reinforcing steels - Part 4: Welded fabric.

DIN 488-5: Reinforcing steels - Part 5: Lattice girders.

DIN 488-6: Reinforcing steel - Part 6: Assessment of conformity.

BS EN ISO 15630-1: Steel for the reinforcement and prestressing of concrete. Test methods. Reinforcing bars, wire rod and wire.

BS EN ISO 15630-2: Steel for the reinforcement and prestressing of concrete. Test methods. Welded fabric.

Commonly used steel bar production standards in China:

(1) Steel for reinforced concrete Part 1: Hot-rolled smooth round steel bar GB/T 1499.1-2017

(2) Steel for reinforced concrete Part 2: Hot-rolled ribbed steel bars GB1499.2-2018

(3) Steel for reinforced concrete Part 3: Welded steel mesh GB1499.3-2010

(4) Quenching and self-tempering ribbed bars for the reinforcement of concrete GB13014-2013

(5) Low carbon steel hot-rolled round wire rod GB/T701-2008

(6) Cold-rolled ribbed steel bar GB/T 13788-2017

(7) Steel wire for prestressed concrete GB/T 5223-2014

(8) Steel strand for prestressed concrete GB/T 5224-2014

(9) Cold-drawn spiral steel bar DBJ14-BG3-96

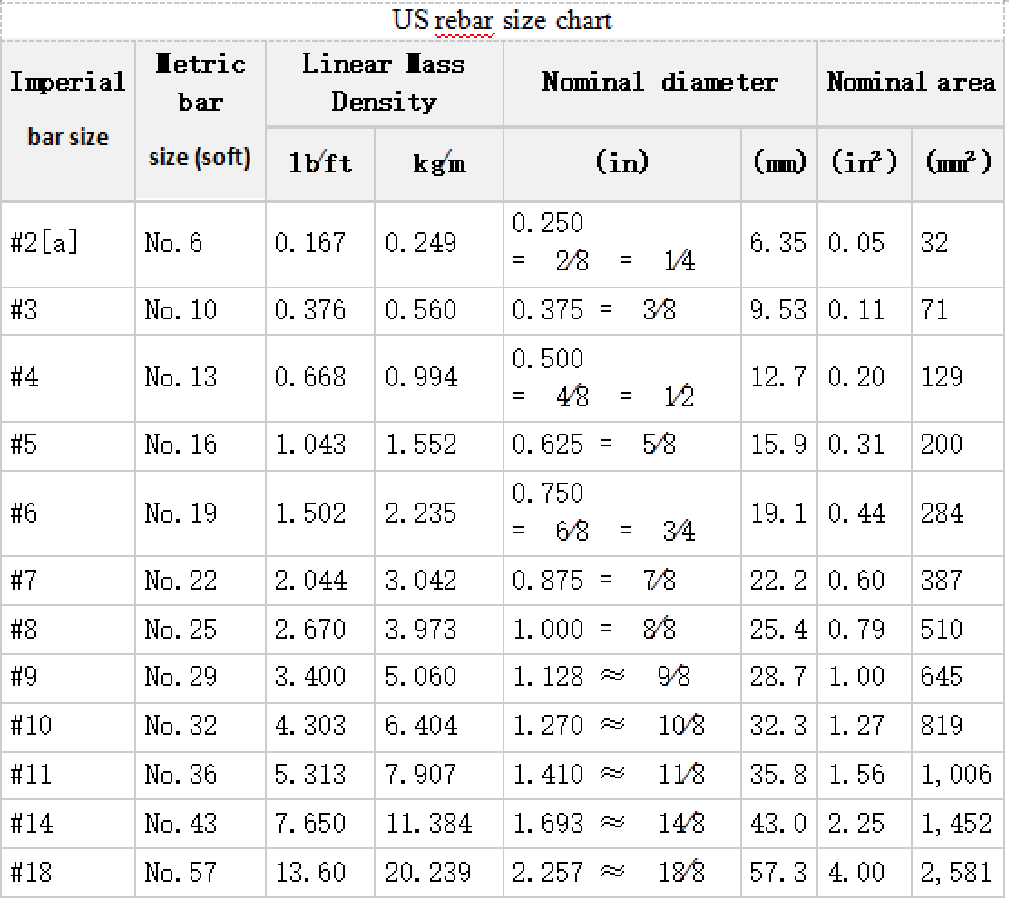

US sizes

US/Imperial bar sizes give the diameter in units of 1⁄8 inch (3.2 mm) for bar sizes #2 through #8, so that #8 = 8⁄8 inch = 1-inch (25 mm) diameter.

There are no fractional bar sizes in this system. The "#" symbol indicates the number sign, and thus "#6" is read as "number six". The use of the "#" sign is customary for US sizes, but "No." is sometimes used instead. Within the trades rebar is known by a shorthand utilizing the bar diameter as descriptor, such as "four-bar" for bar that is four-eighths (or one-half) of an inch.

The cross-sectional area of a bar, as given by πr², works out to (bar size/9.027)², which is approximated as (bar size/9)² square inches. For example, the area of #8 bar is (8/9)² = 0.79 square inches.

Bar sizes larger than #8 follow the 1⁄8-inch rule imperfectly and skip sizes #12–13, and #15–17 due to historical convention. In early concrete construction bars of one inch and larger were only available in square sections, and when large format deformed round bars became available around 1957,[21] the industry manufactured them to provide the cross-sectional area equivalent of standard square bar sizes that were formerly used. The diameter of the equivalent large format round shape is rounded to the nearest 1⁄8 inch to provide the bar size. For example, #9 bar has a cross section of 1.00 square inch (6.5 cm2), and therefore a diameter of 1.128 inches (28.7 mm). #10, #11, #14, and #18 sizes correspond to 11⁄8 inch, 11⁄4, 11⁄2, and 2-inch square bars, respectively.[22]

Sizes smaller than #3 are no longer recognized as standard sizes. These are most commonly manufactured as plain round undeformed rod steel but can be made with deformations. Sizes smaller than #3 are typically referred to as "wire" products and not "bar" and specified by either their nominal diameter or wire gage number. #2 bars are often informally called "pencil rod" as they are about the same size as a pencil.

When US/Imperial sized rebar are used in projects with metric units, the equivalent metric size is typi

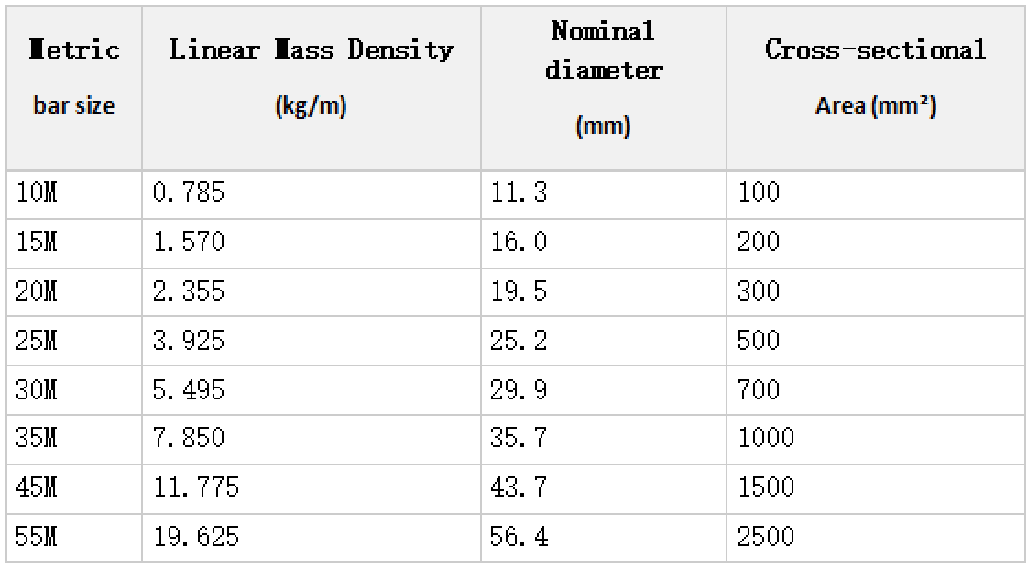

Canadian sizes

Metric bar designations represent the nominal bar diameter in millimeters, rounded to the nearest 5mm.

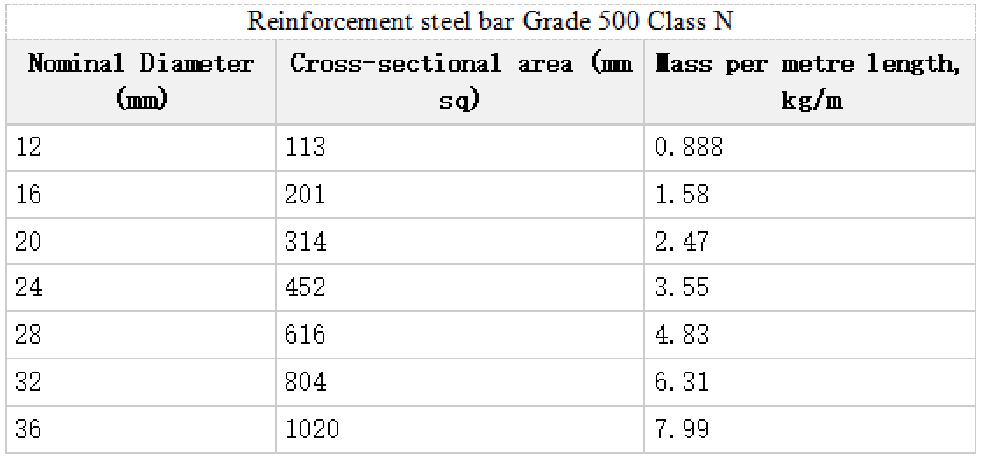

Australian sizes

Reinforcement for use in concrete construction is subject to the requirements of Australian Standards AS3600 (Concrete Structures) and AS/NZS4671 (Steel Reinforcing for Concrete). There are other standards that apply to testing, welding and galvanizing.

The designation of reinforcement is defined in AS/NZS4671 using the following formats:

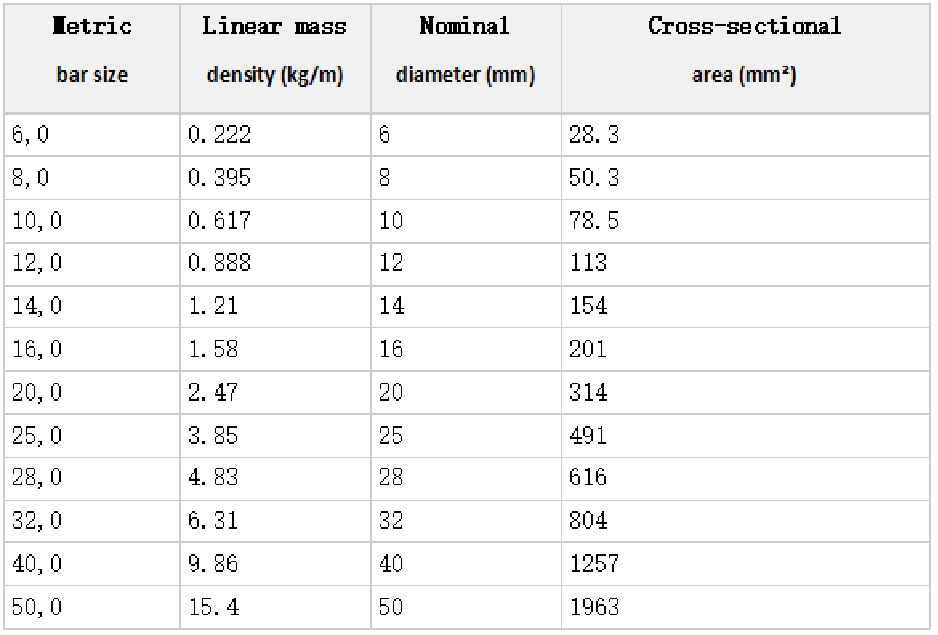

European sizes

Metric bar designations represent the nominal bar diameter in millimetres. Preferred bar sizes in Europe are specified to comply with Table 6 of the standard EN 10080,[23] although various national standards still remain in force (e.g. BS 4449 in the United Kingdom). In Switzerland some sizes are different from European standard.

Shape/ Section

D- deformed ribbed bar, R- round / plain bar, I- deformed indented bar

Ductility Class

L- low ductility, N- normal ductility, E- seismic (Earthquake) ductility

Standard grades (MPa)

250N, 300E, 500L, 500N, 500E

Examples:

D500N12 is deformed bar, 500 MPa strength, normal ductility and 12 mm nominal diameter – also known as "N12"

Bars are typically abbreviated to simply 'N' (hot-rolled deformed bar), 'R' (hot-rolled round bar), 'RW' (cold-drawn ribbed wire) or 'W' (cold-drawn round wire), as the yield strength and ductility class can be implied from the shape. For example, all commercially available wire has a yield strength of 500 MPa and low ductility, while round bars are 250 MPa and normal ductility.

New Zealand

Reinforcement for use in concrete construction is subject to the requirements of AS/NZS4671 (Steel Reinforcing for Concrete). There are other standards that apply to testing, welding and galvanizing.

'Reinforcement steel bar Grade 300 & 500 Class E

India

Rebars are available in the following grades as per IS:1786-2008 FE 415/FE 415D/FE 415S/FE 500/FE 500D/FE 500S/FE 550, FE550D, FE 600. Rebars are quenched with water at a high level pressure so that the outer surface is hardened while the inner core remains soft. Rebars are ribbed so that the concrete can have a better grip. Coastal regions use galvanized rebars to prolong their life. BIS rebar sizes are 10, 12, 16, 20, 25, 28, 32, 36, 40 and 50 millimeters.

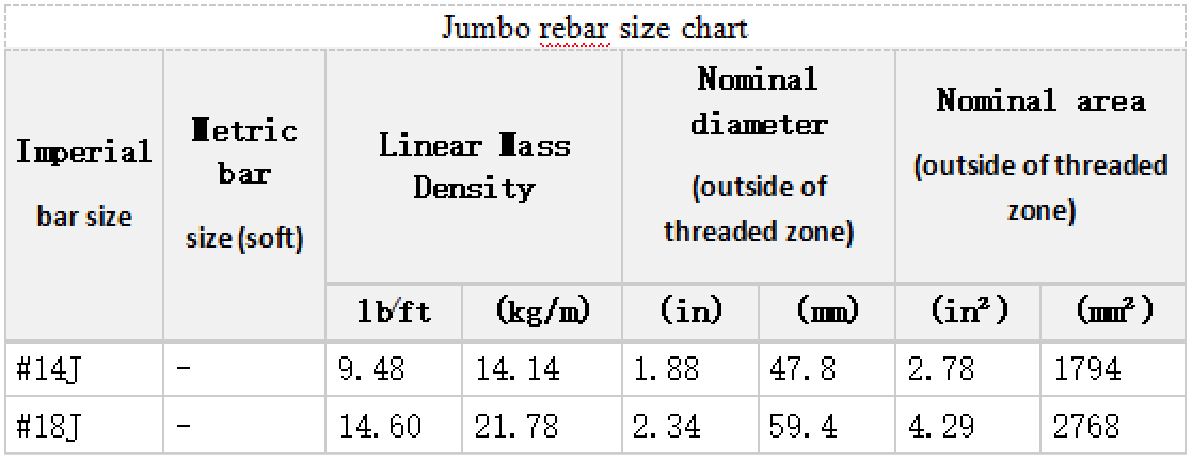

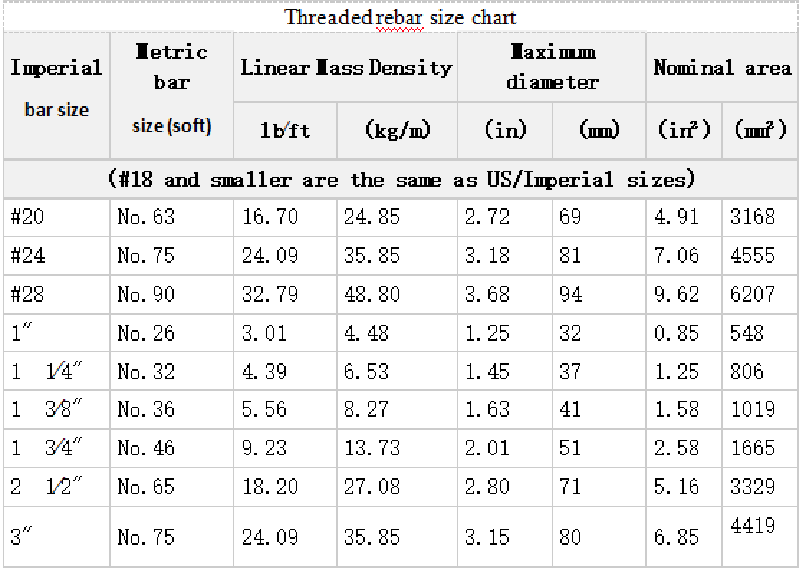

Jumbo and threaded bar sizes

Very large format rebar sizes are widely available and produced by specialty manufacturers. The tower and sign industries commonly use "jumbo" bars as anchor rods for large structures which are fabricated from slightly oversized blanks such that threads can be cut at the ends to accept standard anchor nuts.[24][25] Fully threaded rebar is also produced with very coarse threads which satisfy rebar deformation standards and allow for custom nuts and couplers to be used.[26] These customary sizes, while in common use, do not have consensus standards associated with them, and properties may vary by manufacturer.