Prepainted steel coil, also known as pre-coated steel coil or color-coated steel coil, is a product made of hot-dip galvanized steel sheet, hot-dip galvalume steel sheet, electro-galvanized steel sheet, etc. that has been coated with one or more layers of organic paint or other protective coatings.

The prepainting process protects the metal substrate from corrosion. It improves its durability and aesthetic appearance and provides a wide range of color choices.

According to the EN-10169-1 standard, an organic coating material is applied to the rolled metal strip to protect it from corrosion. Cleaning and pretreatment of chemicals are applied to one or both sides of the metal surface with a single or multiple coats of paint or powder.

Prepainted steel coils are widely used in various applications, such as:

1.Indoor and outdoor applications in building and construction (roofing, wall cladding, garage doors)

2.Domestic appliances (refrigerators, washing machines, bakeware)

3.Cabinets and office furniture

4.Transport and automotive sectors

5.Lighting fittings

Prepainted steel coils come in a variety of color coatings, surface textures, and gloss levels. The paint coatings have high chemical resistance, flexibility, and non-stick properties.

The coated coils are available in different cuts. Customers may request coils with narrow widths, profiled, deep drawn, and different lengths and shapes. There are a variety of prepainted steel coils as manufacturers continue to develop modern designs and coatings.

The main features and advantages of prepainted steel coil are obvious, and are widely recognized and used in large quantities through these features:

1. Good durability, corrosion resistance and longer service life compared with galvanized steel sheets.

2. Good heat resistance, compared with galvanized steel sheet, it is not so easy to fade under high temperature.

3. Excellent heat reflectivity.

4. Color-coated coils have similar processing performance and spraying performance to galvanized steel sheets.

5. Excellent welding performance.

6. Color-coated rolls have excellent performance-price ratio, durable performance and competitive price.

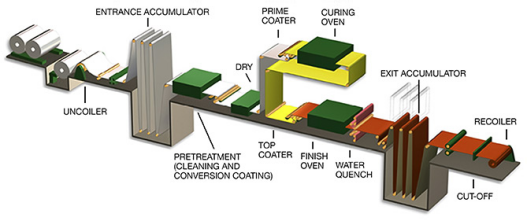

Prepainted steel coil usually go through the following processing steps:

Step 1: Cleaning the Metal Strip

Cleaning up the oil, dirt, and impurities of the cold-rolled coil involves brushing, an alkaline dip, a water bath, or brushing.

Step 2: Application of Zinc and Alloy

The application of aluminum and zinc depends on the application and customer requirements. Some products consist of 100 percent zinc, while others contain magnesium alloy.

Step 3: Treatment of the Surface

This step is vital to ensuring that the paint and primer bond well with the metal strip. Due to some chemical restrictions, the surface is treated with chemicals, such as alkaline oxidation, depending on the supplier and country of origin.

Step 4: Metal Rinsing and Drying

Rinsing the metal strip helps ensure that it has no chemical residue before applying primer. Drying the metal is a must to ensure that the subsequent layers bond well.

Step 5: Application of Primer

A coating of primer can be on one or both sides of the metal strip. Primer application hastens the adhesion of the finished paint layer.

Step 6: Curing and Cooling the Strip

Curing takes 15 to 16 seconds. This method allows the primer to harden, dry, and reach the desired temperature before applying the next coating.

Step 7: Front and Back Coating

This step is the final painting stage, wherein two-coat paint systems are applied.

Step 8: Drying, Curing, and Cooling

The product undergoes this step to ensure that the steel product is ready for rewinding, rerolling, and shipping to end users.

Step 9: Packaging

Image showing a coil coating line schematic.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: