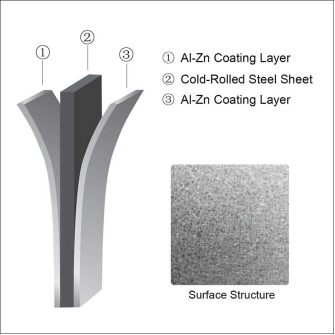

Galvalume steel sheet & coil is also called Aluminum-Zinc Alloy Coated Steel, Zincalume steel, aluminized zinc steel (aluzinc steel), SGLC, The galvalume metal is composed of 55% aluminium, 43.4% zinc and 1.6% silicon solidified at 600 ~C. Its whole structure consists of aluminium-iron-silicon-zinc, forming a compact quaternary crystal alloy. The surface of the Galvalume steel sheet & coil is characterized by smooth, flat and gorgeous stars, and its base color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of galvalume steel sheet is up to 25a, and its heat resistance is good. It can be used in high temperature environment at 315 C. The adhesion between coating and paint film is good, and it has good processing performance. It can be punched, sheared and welded. The surface conductivity is very good.

The surface of the galvalume steel sheet & coil is smooth, flat and gorgeous with star flowers, and the base color is silvery white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the galvalume steel sheet & coil can reach 25a, the heat resistance is very good, and it can be used in a high temperature environment of 315°C; the adhesion between the coating and the paint film is good, and it has good processing performance, and can be stamped, cut, welded, etc. ; Surface conductivity is very good.

Layer Schematic of Galvalume Steel

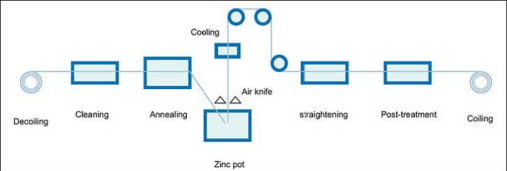

Production Process of Hot-dip Al-Zn Coating

Step 1:

Pre-treatment: After the cold-rolled coil arrives in the galvalume workshop, after passing through the uncoiler, through the degreasing section and the reduction furnace, the steel coil is cleaned and its components are reduced to the extent that it can be galvanized.

Step 2:

Central section: The most critical technology is this step. After passing through the zinc pot, a layer of zinc layer is plated on the surface of the steel plate. After coming out of the zinc pot, it is cooled and shaped by the cooling tower.

Step 3:

Post-processing: The steel plate finally comes to the post-processing stage after various processes. After finishing, straightening and passivation, and finally coiling.

Characteristics of Galvalume Steel Sheet & Coil

Machinability

It can satisfy the processing requirements of rolling, coiling and others processes alike.

2.Thermal resistance

Common HDG steel plate normally works under 230℃, and has its color changed at 250℃, however, Galvalume steel plate cansustain the environment at 315℃ for long time.

3.High reflectivity

Reflection ability of heat and light is twice as much as those ofhot-dip zinc steel sheet, and its reflectivity is more than 0.70, exceeding 0.65 (required by the EPA Energy Star Standard), which is an ideal construction materials of saving energy.

4.Resistance to corrosion

Al-Zn coated steel sheet has better performance in corrosion resistance than GI sheet of the same thickness and its service life is 2-6 times longer than general GI sheet.

The use of galvalume steel sheet & coil

1.Appliances Industry

Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

2.Industrial Instruments

Electric control cabinet, industrial refrigeration equipment, automatic vending machine.

3.Architecture

Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

4.Agriculture

Piggery, chicken coop, granary, greenhouse pipes, etc.

5.Other

Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway.

As a new type of building material, galvalume steel sheet & coil are constantly improving through research and development technology, and strive to achieve high-quality performance delivered to meet customer requirements. With the development of technology, the application prospect of galvalume steel sheet & coil in the construction industry will become wider and wider, and it will also provide more possibilities for the construction industry.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: