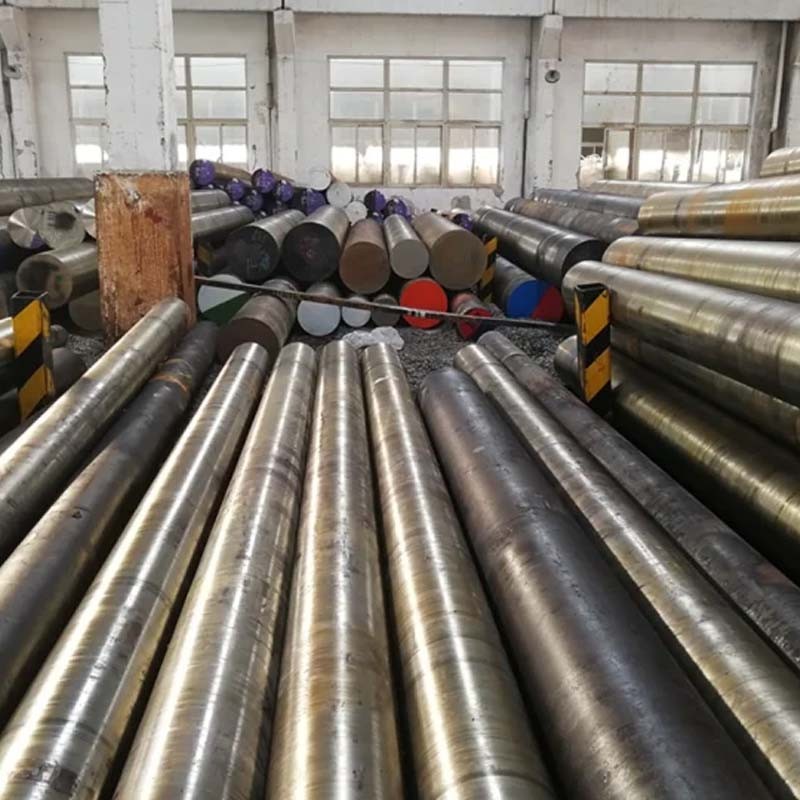

Round steel refers to strip steel whose solid cross-section is circular. Its specifications are expressed in millimeters of diameter, such as "50" means a round steel with a diameter of 50 mm. There are three types of round steel: hot-rolled, forged and cold-drawn. The specification of hot-rolled round steel is 5.5-250 mm. 5.5-25 mm small round steel is mostly supplied in straight bundles, which are often used in steel bars, bolts and various mechanical parts; round steel larger than 25 mm is mainly used in the manufacture of mechanical parts and seamless steel pipe billets.

Alloy structural steel round steel is an industrial part material made of various steel materials. Due to its high hardness and strong wear resistance, it is used as a material in various industries and has a wide range of applications.

The characteristics of alloy structural steel round steel:

1. Use high-quality ultra-fine tungsten carbide and imported cobalt powder as raw materials.

2. Adopt the world's advanced low-pressure sintering preparation technology for standardized production.

3. High strength and hardness.

4. It has good hardness, good wear resistance, high elastic modulus, high bending strength, good chemical stability (acid resistance, alkali resistance, high temperature oxidation), good impact resistance toughness, low expansion coefficient, thermal conductivity, electrical conductivity and iron and The characteristics of its alloys are similar.

5. High-tech precision advanced equipment: 10MPa low-pressure sintering furnace imported from Germany for sintering.

6. Product features: There are many grades of materials, which can be applied to the needs of different uses, with complete specifications and accurate blank sizes (reducing the amount of processing and improving production efficiency).

Low-alloy ultra-high strength , good comprehensive mechanical properties after heat treatment, good hardenability, weldability and formability, but poor corrosion resistance and oxidation resistance, and the service temperature is generally lower than 200 °C. It is suitable for use after austempering or low temperature tempering.

Alloy structural steel round steel is widely used in the manufacture of heavy-duty, high-strength, high-toughness parts and high-strength components.

Such as: aircraft landing gear, high-pressure blower blades, etc., can partially replace the corresponding chromium-nickel-molybdenum steel when manufacturing middle and lower section parts.

Used to manufacture various bearing rings and rolling bodies, such as steel ball rollers and rings for internal combustion engines, electric motorcycles, automobile tractors, machine tools, rolling mills, boring machines, mining machinery, general machinery, high-load machinery, etc. High-speed rotating machinery transmission bearings. It is also sometimes used to make tools, such as dies and gages.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: