Recently, Shougang Tonggang making Division has received good news. With the joint efforts of all staff, the division has successfully rolled the low-alloy high-strength Q355B checkered plate for the first time. After inspection, all indicators of the product meet the standard requirements, creating good conditions for the company to expand product varieties and specifications and open up the checkered plate market.

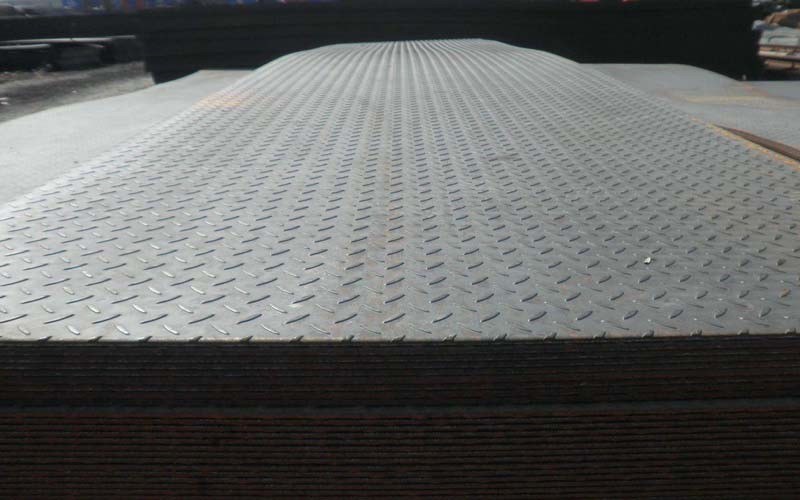

Patterned plate is a steel plate with regular patterns or textures on the surface. Common shapes include lentils, diamonds, round bean, etc. It is not only beautiful in appearance, but also has good anti-slip and wear-resistant functions. It is easy to clean and saves steel. It is widely used in construction, shipbuilding, transportation, machinery manufacturing and other industries.

To ensure the successful rolling of this type of steel, the Steelmaking Division actively conducted discussions with Tonggang International Trade on the various requirements raised by customers. It organized key technical personnel from the rolling line to form a research group to fully discuss the key points and difficulties in production organization and product control, and finally reached a consensus.

After communicating and coordinating with the manufacturing department, the Steelmaking Division arranged the trial rolling of the low-alloy high-strength Q355B patterned plate to be carried out in the last furnace at the end of the normal production casting. Since it was the first attempt to roll the patterned plate, the corresponding pressure distribution data model was the key to the success of the rolling. The research team held many discussions and established a new distribution model based on the production experience of previous steel varieties. Then, through offline simulation and optimization, this model was successfully applied to actual production, laying a solid foundation for the smooth progress of the rolling work. At the same time, in order to ensure that the pattern height meets the standard, the division carefully calculated and selected the method of soft-shaking F5 frame, and used the F4 frame as the finished product frame for rolling to ensure that the patterned plate meets the use requirements.

After half a month of thorough preparation, the rolling of this specification was smooth and stable, the measured pattern height met the standard requirements, and the trial rolling was a one-time success.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: