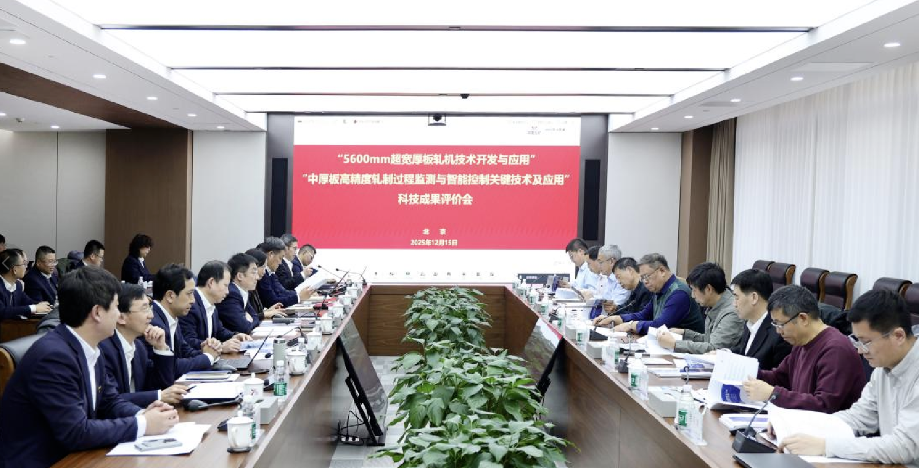

Recently, a scientific and technological achievement evaluation meeting jointly organized by the China Iron and Steel Association and Metallurgical Corporation of China Ltd. (MCC) was held in Beijing. Two key technological achievements independently developed by China Metallurgical Engineering Research Institute(CERI) passed the authoritative evaluation. Specifically, the "Development and Application of 5600mm Ultra-Wide and Thick Plate Rolling Mill Technology" was recognized as having reached the international leading level in overall technology; and the "Key Technologies and Applications of High-Precision Rolling Process Monitoring and Intelligent Control for Medium and Thick Plates" was recognized as having reached the international advanced level. This marks a key breakthrough for China in the field of high-end wide and thick plate rolling, and is of great significance for ensuring the supply of high-end steel materials and promoting the construction of a manufacturing powerhouse.

The world's first ultra-wide and thick plate rolling mill sets a new industry benchmark.

The "Development and Application of 5600mm Ultra-Wide and Thick Plate Rolling Mill Technology" project, employing a fully domestically produced model, successfully developed the world's first 5600mm ultra-wide and thick plate rolling mill. It boasts comprehensive advantages, including the widest rolled products, the greatest rolling force, the highest mill rigidity, and the best accuracy in plate thickness and crown. The project significantly improved control precision and stability through optimized mill structure and transmission system design; innovative manufacturing processes resulted in the development of an ultra-large mill stand weighing 425 tons and ultra-large φ2400mm support rolls, greatly enhancing equipment durability; and the development of a high-precision AGC system further ensured production efficiency and product quality. This technology has obtained 13 invention patents and has been successfully applied at Angang Zhoukou Steel in Henan Province, yielding significant economic and social benefits.

Intelligent Control System Solves Production Precision Challenges

Faced with the complex rolling conditions and high quality control difficulties in the medium and heavy plate rolling industry, the "Key Technologies and Applications of High-Precision Rolling Process Monitoring and Intelligent Control for Medium and Heavy Plates" project has constructed an intelligent technology system covering the entire process. This achievement achieves precise perception and fault prediction of the production process through panoramic monitoring and intelligent diagnostic technology; it effectively coordinates multi-parameter control by integrating artificial intelligence algorithms and mechanism models, overcoming the challenge of thickness and shape optimization; and it has developed a new AGC algorithm and fault-tolerant strategy, enabling stable control of the same-plate difference in steel plates below 20 mm within a micrometer-level precision of ±0.1 mm. Currently, this achievement has resulted in multiple patents, standards, and software copyrights, and has been successfully applied in companies such as Nanjing Iron & Steel, Jiujiang Pinggang, and Baosteel Zhanjiang Iron & Steel.

CERI stated that it will take this breakthrough as an opportunity to accelerate the promotion and application of technological achievements, continuously deepen industry-university-research cooperation, focus on key industry needs, help China's steel industry achieve a strategic transformation from "scale leadership" to "technology leadership", and provide solid technical support for building a world-class steel industry cluster.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: