Wire drawing is a metalworking process used to reduce the cross-section of a wire by pulling the wire through a single, or series of, drawing die(s). There are many applications for wire drawing, including electrical wiring, cables, tension-loaded structural components, springs, paper clips, spokes for wheels, and stringed musical instruments. Although similar in process, drawing is different from extrusion, because in drawing the wire is pulled, rather than pushed, through the die. Drawing is usually performed at room temperature, thus classified as a cold working process, but it may be performed at elevated temperatures for large wires to reduce forces.[1]

Of the elemental metals, copper, silver, gold, and platinum are the most ductile and immune from many of the problems associated with cold working.

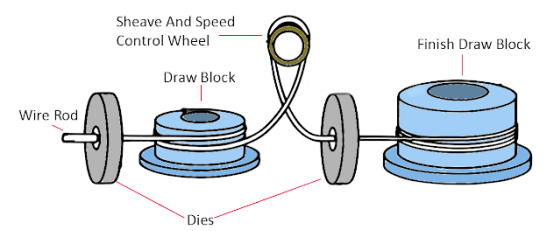

Stages of Wire Drawing Process

The wire drawing process can be divided into several stages, each with its own specific tasks and requirements. Here we discuss about how to draw metal

1. Preparation of the Wire

Before the wire is drawn, it must be prepared. This involves cleaning the wire to remove dirt or impurities and applying a lubricant to reduce friction during the drawing process. lnitially, the rods used for wire drawing are pickled in acid to eliminate any scale buildup and then electrically butt welded. lron hydroxide, copper, or tin coating may be applied to the rod during or after the pickling process.

Large hot rolled coils around 10mm in diameter undergo preparatory treatment prior to actual wire drawing. The preparation treatment for steel wire consists of,

1)Cleaning. This may involve acid pickling, rinsing, drying the coil, or mechanical flexing

2)Neutralization, The raw material is then immersed in a lime bath to neutralize residual acid

2. Pointing the Wire

The wire's end must be pointed so that it can be easily inserted into the die. This is typically done using a wire pointing machine or by hand using a file.

3. Drawing the Wire

The wire is fed through the first die and pulled by a powerful motor or capstan, As the wire is drawn through the die, its diameter is reduced, and its length increases. The process is repeated through a series of dies until the desired diameter is achieved

4. Annealing

As the wire is drawn, it becomes harder and stronger. lt can also become more brittle. In some cases, the wire may need to be annealed to relieve the stress and strain caused by the drawing process. Annealing involves heating it to a specific temperature and then cooling its lowly at room temperature or quenching it, Annealing is done to the wire to soften the meta and make it more ductile for further drawing or fabrication steps. The annealing process reduces the strength of the wire but makes it less brittle.

5. Finishing and Final Steps

Depending on the application, the wire will have a consistent diameter ranging from a fraction of a millimeter to several millimetres. The properties of the wire, like strength, conductivity,and hardness, can be tailored based on the initial material and specifics of the wire drawing process. Once the wire has been drawn to its final diameter, it may undergo additional finishing processes, such as coating or plating, to enhance its properties or appearance. Then wire undergoes final cleaning, cutting, and packaging for sale and distribution. To prevent rust.some wires may receive additional finishes, such as galvanization, The wire may be spooled for sale as is or fed into another manufacturing line as input.

Application

There are many different forms of metal surface treatment.

For example: sandblasting (forming matt pearl silver surface), polishing (mirror forming), embossing (pressing various textures), electroplating (covering a layer of other metals), Spray (covers other non-metallic coatings), as wire drawing (forms a satin-like effect). Compared to other surface treatments, wire drawing gives the metal surface a non-mirror-like metallic luster, which has a very strong decorative effect like silk satin. It is like giving ordinary metals new life and life, so wire drawing has more and more market recognition and wide application.

In the construction industry there are elevator door panels, escalator decorative panels, Leading, hinge, handle, lock trim, etc. in the architectural hardware industry; Kitchenware such as range hoods, stainless steel cookers, sinks, etc. The rise of various 3C digital products in recent years has pushed the application of wire drawing to a climax, such as the notebook computer panel, keyboard board, mobile phone panel, LCD frame, battery cover, camera protection slider, Digital camera lens slide cover and so on. There are other various electronic products, such as: Mp3, Mp4, DVD players, projectors, and so on. And what we commonly find are locks, furniture, luggage accessories and so on.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: