Stainless steel is a strong and highly durable material ideal for both interior and exterior structural and design features. Using stainless steel color coated sheet means that design professionals can incorporate elements of color into their designs, rather than opting for a regular stainless steel look. Chinese cstainless steel color coated sheet not only has the unique luster and strength of metal, but also has colorful and long-lasting colors. Stainless steel color coated sheet not only maintains the physical, chemical and mechanical properties of primary color stainless steel, but also has stronger corrosion resistance than primary color stainless steel.

In recent years, due to its uniqueness, stainless steel color coated sheet have been used more and more widely. Now, a large number of stainless steel color coated products are used for decoration in buildings abroad, and stainless steel color coated sheet have become all the rage. Chinese stainless steel color coated sheet not only has the unique luster and strength of metal, but also has colorful and long-lasting colors. Stainless steel color coated sheet not only maintains the physical, chemical and mechanical properties of primary color stainless steel, but also has stronger corrosion resistance than primary color stainless steel. Therefore, since it came out in the 1970s, it has been widely used in the fields of building materials, chemicals, automobiles, electronics, and arts and crafts.

Among the commonly used primary color stainless steels, austenitic stainless steel is the most suitable coloring material, and a satisfactory color appearance can be obtained. Due to the increased possibility of corrosion in the coloring solution of ferritic stainless steel, the color obtained is not as bright as the former. However, low-chromium high-carbon martensitic stainless steel can only get a dark color or a black surface due to its poor corrosion resistance. According to reports, after austenitic stainless steel is colored by low-temperature surface oxidation treatment coloring method, it is exposed to industrial atmosphere for 6 years, exposed to marine atmosphere for 1.5 years, soaked in boiling water for 28 days, or heated to about 300 °C , its color luster did not change. In addition, it can withstand general molding, drawing and bending, and work hardening. WiQ Industrial Design. China At present, colored stainless steel can be used in many other fields besides building exterior walls and window frame decoration. For example, black stainless steel plates can be used to make solar collector panels, and their selective heat absorption rate can reach 91% to 93%. In the field of arts and crafts, combining colored stainless steel with printing, etching, grinding and dot method can be used to produce three-dimensional relief murals and hanging screens that will never fade. In addition, the use of stainless steel color coated sheet to manufacture household appliances, cooking utensils, kitchen equipment, and bathroom appliances will be deeply loved by consumers.

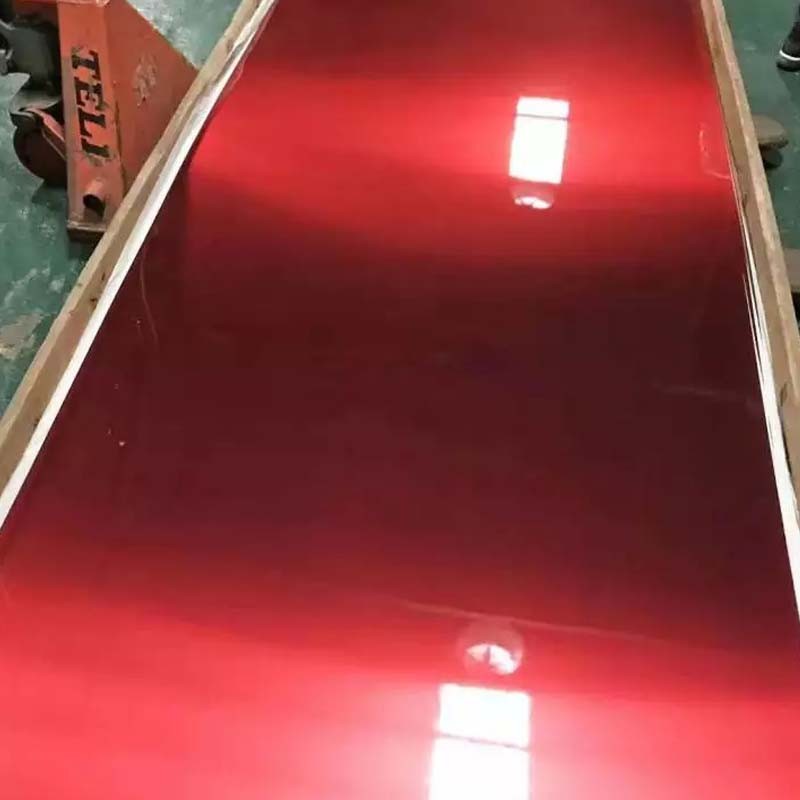

The current stainless steel color coated sheet plate is gorgeous in color and is a very good decorative material. At the same time, the stainless steel color coated sheet has strong corrosion resistance, high mechanical properties, and the color surface layer does not fade for a long time. The color will change with the different light angles, etc. Features, the stainless steel color coated sheet and the color surface layer can withstand the temperature of 200 ℃, the salt spray corrosion resistance is better than that of ordinary stainless steel, the wear resistance and scratch resistance of the colored stainless steel plate are equivalent to the performance of the foil layer coated with gold. When the colored stainless steel plate is bent at 90°C, the colored layer will not be damaged. It can be used as hall wall panels, ceilings, elevator car panels, car box panels, architectural decoration, signboards, etc. Stainless steel color coated sheet are generally used for decorative walls.

Stainless steel color coated sheet have become a beautiful cluster in the stainless steel series; professionally produce colored stainless steel vacuum-coated titanium gold plates, complete colors, can be plated with gold, champagne gold, black gold, gun black, silver white, silver gray, bronze, bronze, Rose gold, purple gold, coffee gold, sapphire blue, colorful, brown, etc., titanium plate material is stainless steel 201, 202, 304, etc.; surface 8K, 2B, BA, brushed, No.3, No.4; stainless steel plate, BA plate , 8K mirror panel, titanium gold plate, frosted plate, etched flower plate, embossed plate, etc.,

1. A new process called no-fingerprint processing technology can be used on the surface of stainless steel color coated sheet. This technology mainly uses nano-layer technology to form an extremely thin and very strong protective layer on the surface of cstainless steel color coated sheet, because it can avoid human fingers. Fingerprints are left after touching, so it is also called stainless steel color coated sheet without fingerprints. The fingerprint-free treatment process can be processed on stainless steel color coated sheet mirror panels, brushed panels, frosted panels, etched panels, etc. to obtain the effect of no fingerprints, which can be very good Enhanced anti-rust function.

2. The plasticity of the colored stainless steel plate is strong, which has changed the defects of the rigid installation of wooden materials, and as a metal material, it also has more excellent flame retardancy, mildew resistance, corrosion resistance, moisture resistance, green environmental protection, etc. The color is passed Processed by vacuum ion plating, the color layer on the surface is rich and firm, especially the brushed board or frosted board, which has better wear resistance than other surface textures.

4. Thestainless steel color coated sheet has changed the feeling of unsteadiness of the wooden plate, and it is stronger than the wooden material and increases the anti-sinking property of the product floor.

5. Materials such as stone and wood are relatively easy to mold or weather when exposed to water for a long time in the kitchen, and other metal materials are not suitable for kitchen decoration in moisture, so stainless steel color coated sheet is far more suitable than other materials. Cabinet decoration. However, this metal material also has good or bad quality. Generally, 201 and 304 stainless steel plates are commonly used, but 304 material plates will have stronger rust resistance.

Advantages of stainless steel color coated sheet:

1. Colored stainless steel is an environmentally friendly decorative material that does not contain organic matter such as methanol, has no radiation, is safe and fireproof;

2. On the basis of stainless steel, there are now stainless steel color coated sheet, stainless steel etching technology, stainless steel fine grinding mirror surface, sand surface, wire drawing and other processing methods, which make the stainless steel plate more and more brilliant; through etching technology, it can be depicted on the instant noodles of stainless steel Produce a variety of graphics, text, and have a sense of three-dimensional, concave-convex, bid farewell to the shortcomings of traditional stainless steel plate monotonous color and picture;

3. The stainless steel color coated sheet is a chemical reaction on the surface of the stainless steel, so that a layer of oxide layer is formed on the surface of the stainless steel plate, the stainless steel and the oxide layer are integrated, the color of the plated color is bright, and it does not fade;

4.Stainless steel color coated sheet has metal luster and hardness, easy to clean, not easy to damage, scratch; can well compensate for acid and alkali corrosion, not easy to rust.

Stainless steel color coated sheet has a wide range of commercial applications including exterior and interior cladding, signage, elevator interiors and wall cladding. Due to their modern and sleek look, they are also frequently used in retail and hospitality spaces for decorative features such as feature walls, ceilings and fixtures.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel weight calculation |

| Contact us | Answers | |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: