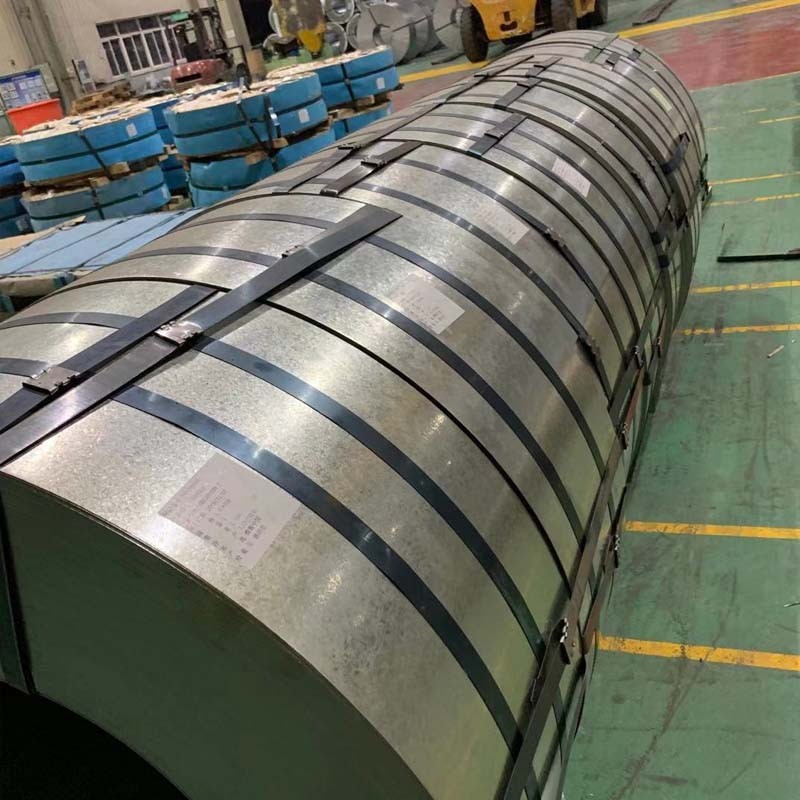

Cold rolled steel strip refers to hot-rolled strip steel and steel plate as raw materials, which are rolled into strip steel and thin plate by cold rolling mill at room temperature. The hot-rolled steel strip is used as the raw material, and it is rolled into a product by a four-roll or six-roll cold rolling mill at room temperature. Strip steel with a thickness of less than 0.2mm is called ultra-thin strip steel or foil, which is made of cold-rolled strip steel and further processed, usually rolled by a multi-roll mill.

As a thin steel, cold-rolled strip steel is mainly used in the construction field, including steel for building structures, steel for construction, steel for auto parts, steel for motors, steel for electrical materials, steel for pipes, etc. It has the advantages of high strength, wear resistance, fatigue resistance and corrosion resistance.

The varieties of cold-rolled strip mainly include carbon structural steel plate alloy and low-alloy steel plates, stainless steel plates, and other special steel plates, etc.

The main advantages of cold rolled steel strip are:

① It is possible to obtain extremely thin steel strips that are difficult to obtain by hot rolling

②It can make the product have very high and wide range of mechanical properties and process properties.

③ During the cold rolling process, no iron scale is produced on the surface of the rolled piece, and it is pickled before rolling, so the surface quality of the product is good, and various special surfaces can be given to the strip according to requirements, such as rough surface, suede surface or polished surface, etc.;

④ High rolling speed and high productivity.

Process characteristics of cold rolled steel strip :

① When the strip steel is rolled in a cold state, due to the work hardening of the strip steel, it must undergo intermediate annealing to soften it again and restore its plasticity in order to continue rolling.

② The surface oxide scale must be removed before the strip billet is rolled, so as to ensure the surface finish of the strip and reduce the wear of the roll.

③ Tension rolling is used to ensure the good shape of the strip, control the thickness deviation of the strip, and reduce the rolling pressure, which is beneficial to rolling thin-gauge products.

④ Process cooling and lubrication are used to control the temperature of the roll and the strip, reduce the friction between the roll and the strip and reduce the rolling pressure, which is beneficial to the control of the shape of the strip and prevents the sticking of the strip.

Cold rolled steel strip Applications:

1. Steel for building structure:

One of the important materials of my country's modernization construction, cold-rolled steel strip can be used for exterior design of building background walls, gates, guardrails, etc., and can also be used for structural support of walls and columns. As an important branch of the steel application field for building structures, cold-rolled steel strip has been widely used in the construction of high bridges, long-span buildings, tunnels, roads, and railway bridges. The application of cold-rolled strip steel in the field of building structures can effectively improve the quality and safety factor of buildings.

2. Steel for construction:

Cold rolled steel strip is used as structural steel, and its application cases include bridges, highways, pipelines, and offshore platforms. Cold-rolled strip steel has been more and more widely used in engineering construction due to its advantages of high strength, low deformation rate, and low crack rate. For example, cold-rolled strip steel can be used in structural bridges, construction of pipelines and offshore drilling platforms, not only in a wide range of applications, but also has good toughness and corrosion resistance during use.

3. Steel for auto parts:

The application of cold-rolled strip steel in the field of steel for auto parts is also becoming more and more extensive. For example, it can be used in automotive casings, engine parts, body materials, and more. At present, my country has become one of the largest automobile producing countries in the world, and high-quality cold-rolled strip steel is also playing an increasingly important role in the development of the automobile industry.

4. Steel for electrical materials:

Cold-rolled strip steel is also widely used in the field of steel for electrical materials. For example, it can be used to manufacture transformers, motors, coils, capacitors, solar cells, etc., and is widely used in power equipment, railways, ships, aircraft and other fields. The application of cold-rolled strip steel in the field of electrical materials not only increases the safety and reliability of products, but also improves product performance and quality.

The cold-rolled strip production process mainly controls billet preparation, pickling, cold rolling, annealing and finishing.

Cold-rolled strip steel has various specifications, high dimensional accuracy, good surface quality, mechanical properties and process performance are superior to hot-rolled strip steel, and has broad application prospects. It has been widely used in large-scale industries such as construction, automobile manufacturing, and electrical appliance manufacturing, and has benefited people all over the world with its excellent material properties. In the future, the application of cold-rolled strip steel will become more and more extensive, with continuous innovation and development, it will truly become the benchmark of modernization construction.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: