Cold Rolled Non-Oriented Electrical Steel is a ferrosilicon alloy with low carbon content. In the deformed and annealed steel plate, the grains are randomly oriented. The silicon content of the alloy is 1.5%~3.0%, or the sum of silicon and aluminum content is 1.8%~4.0%. Products are usually cold-rolled plates or strips with nominal thicknesses of 0.35mm and 0.5 mm. lt has the characteristics of high magnetic permeability, low coercive force and large resistance coefficient, so the hysteresis loss and eddy current loss are small. Mainly used as magnetic materials in motors, transformers, electrical appliances and electrical instruments.

The characteristics of cold rolled non-oriented electrical steel:

1, Low iron loss. The most important index of quality, all countries in the world divide the grades by the value of iron loss. The lower the iron loss, the higher the grade and the higher the quality.

2, High magnetic induction intensity.Silicon steel sheets with higher magnetic induction can be obtained under the same magnetic field, and the iron core of motor or transformer manufactured with it has smaller volume and weight, which can save silicon steel sheets, copper wires and insulating materials relatively.

3, High stacking coefficient. The surface of silicon steel sheet is smooth, flat and even in thickness, and the stacking coefficient of manufactured iron core is improved.

4, Good stamping performance. This is more important for manufacturing small and micro motor cores

5.The adhesion and weldability of the surface to the insulating film are good, which can prevent corrosion and improve punching property. F, magnetic aging phenomenon is small g, silicon steel sheet must be delivered after annealing and pickling.

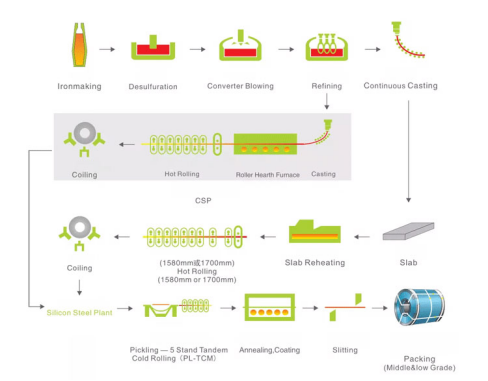

Production Process:

The advantages of cold rolled non-oriented electrical steel lie in its high magnetic permeability, low hysteresis loss, easy magnetization, and high magnetic field strength after magnetization. These characteristics make it have important application value in power equipment.

1. In the transformer, the transformer core is made of cold rolled non-oriented electrical steel, which can improve the efficiency and stability of the transformer. Due to the high magnetization of cold rolled non-oriented electrical steel, it can effectively improve the electronic components, performance and stability.

2. In the automotive field, cold-rolled non-oriented silicon steel is mainly used to manufacture auto parts such as generators, motors, and transmissions. Due to its excellent mechanical properties, it can effectively improve the wear resistance and corrosion resistance of auto parts.

Although the production process of cold-rolled non-oriented silicon steel is relatively complicated, the products are widely used in various types of motors, generators, small transformers, electric welding machines and instruments, etc. At present, it seems that the demand for cold rolled non-oriented electrical steel is still relatively large,sales are still relatively high.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: