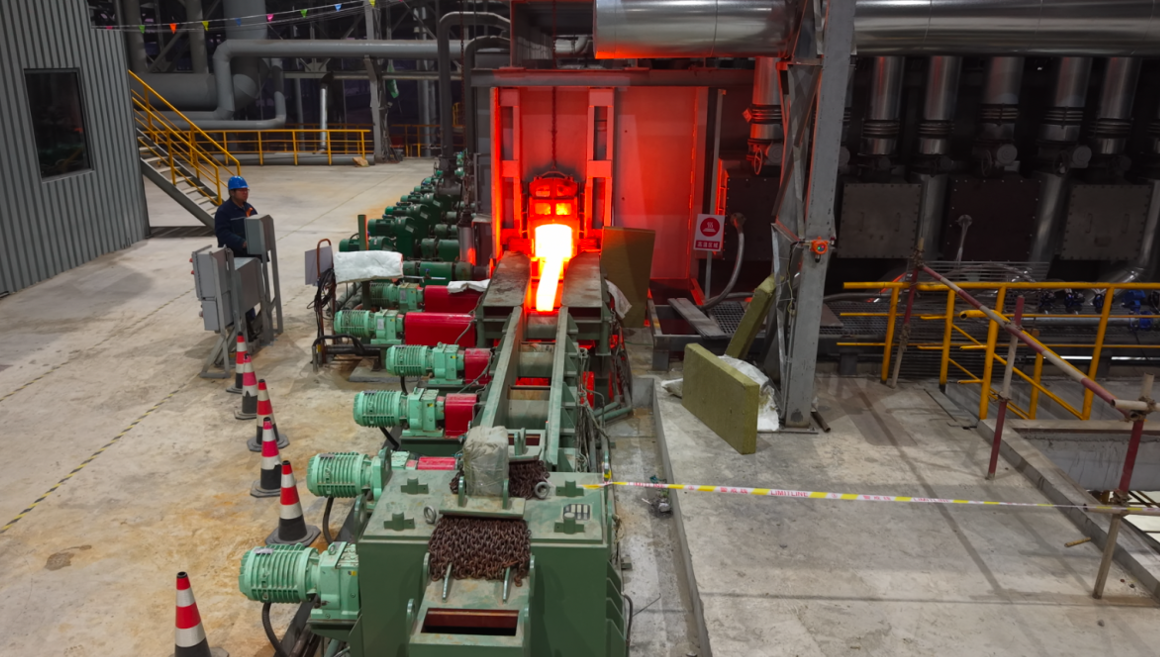

On December 29, 2025, at the Xingtai Iron & Steel Transformation and Relocation Project site in Wei County, Hebei Province, the hot rolling command was issued. Glowing steel billets successively passed through critical equipment including the heating furnace and rolling mill, marking the full commissioning of the large coil production line and the successful completion of its first hot rolling operation. This production line is a crucial component of Xinggang's implementation of the “hydrogen-rich molten reduction + electric furnace” green short-process technology, representing a significant breakthrough in the domestic steel industry's upgrade toward high-end and green production.

The newly commissioned hot-rolling production line for large-diameter coils is a modern facility specializing in the rolling of large-gauge high-quality special steel wire rods. Covering a rolling range of φ16-52mm, it targets high-value-added special steel markets such as premium bearing steel, automotive spring steel, alloy cold heading steel, and non-tempering steel. The entire line incorporates advanced equipment including a high-rigidity short-stress-line mill, a German KOCKS three-roll sizing mill, and the latest generation of American Primetec coilers. It integrates intelligent heating, controlled rolling and cooling, and full-line automation control. This enables free-size rolling with high-precision control, achieving advanced domestic and international standards in energy efficiency, dimensional accuracy, and product performance.

As the core vehicle for Xingtai Iron & Steel's transformation and upgrading, this project employs China's first-of-its-kind short-process technology combining hydrogen-rich molten reduction with electric furnaces. It completely eliminates traditional high-pollution processes such as coking and sintering, tackling environmental challenges in the steel industry at their source and aligning with national industrial restructuring priorities. With a total investment of 13.2 billion yuan, it stands as the region's sole provincial-level key construction project exceeding 10 billion yuan in investment. Upon full operation, it is projected to generate annual revenue surpassing 13 billion yuan, contribute over 1 billion yuan in taxes, and create more than 6,000 jobs.

Chairman Zhang Yuming stated that the successful hot rolling of large coils marks a critical milestone in the relocation project, laying a solid foundation for full-scale commissioning by 2026. Moving forward, Xingtai Iron and Steel will advance the project construction comprehensively by focusing on “ensuring safety, quality, and schedule.” Taking this as a new starting point, the company will strive to build a benchmark for special steel industry clusters, drive breakthroughs in high-end material technologies, and establish green intelligent factories. This will accelerate the strategic transformation from “steel manufacturing” to “material services.”

Weixian County has stated that it will continue to fully support the construction of the Xingtai Iron and Steel project. Focusing on the development directions of high-end, green, and intelligent manufacturing, the county will plan and build a “park-within-a-park” for the special steel industry. It will implement actions to extend, supplement, and strengthen industrial chains, promote the industry's upgrade from raw material processing to material production, accelerate the cultivation of a regionally competitive special steel industrial cluster, and achieve a win-win development of economic and ecological benefits. This initiative aims to provide a model for the high-quality development of China's steel industry.

|

|

|

|

|

| Timely Info | Independent | Platform | Multiple guarantees | Self-operated storage |

| About us | Channel | Useful tools |

|---|---|---|

| About China Steel Market | Prices | Steel Weight Calculation |

| Contact Us | Answers | Why Choose Us |

| Terms & Conditions | Inventory | |

| Privacy Policy | Help |

Hot search words: